When you think about metal structures, rust and decay can be a major concern. Whether it’s bridges, gates, or machinery, exposure to moisture and chemicals can weaken the metal over time. Hot dip galvanizing services offer an effective way to fight this problem. This process helps shield metals, making them last much longer and stay stronger.

What is Hot Dip Galvanizing?

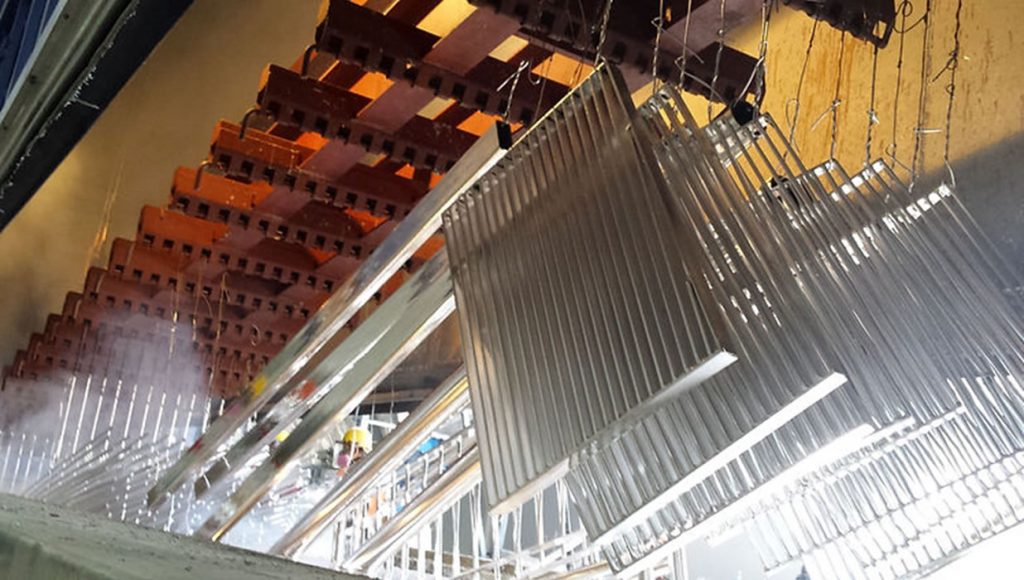

Hot dip galvanizing is a process where metal, usually steel or iron, gets coated with a layer of zinc. The metal is dipped into molten zinc, which bonds tightly with the surface. This creates a strong protective barrier that keeps the metal safe from corrosion. The result? A more durable metal surface that lasts.

The Importance of Hot Dip Galvanizing for Metal Structures

Durability and Longevity

Metal structures are constantly exposed to harsh elements like rain, snow, and chemicals. These conditions can cause the metal to rust and weaken. Hot dip galvanizing gives metal a strong shield against these threats. It increases the lifespan of your structures, keeping them in top shape for years.

Cost-Effective Protection

While hot dip galvanizing may cost more at first, it pays off in the long run. The zinc coating lasts for many years and reduces the need for constant repairs. This lowers maintenance costs. Over time, hot dip galvanizing is a smart investment for saving money.

Corrosion Resistance

The main job of hot dip galvanizing is to protect against corrosion. The zinc layer creates a barrier that prevents moisture and chemicals from reaching the metal. This protection is especially important in industries like construction and agriculture, where metal parts face tough conditions daily.

Better Protection for Hard-to-Reach Areas

Hot dip galvanizing coats the entire surface of the metal, even the tricky spots like corners and seams. Other types of coatings may miss these areas. But with galvanizing, every part of the metal is covered. This ensures complete protection from rust and damage.

Enhanced Strength and Toughness

The zinc coating does more than just stop rust. It also toughens the metal. This extra layer helps the metal resist impacts, scratches, and other types of damage. The metal becomes stronger, so it can handle more pressure and wear without breaking down.

Environmentally Friendly

Hot dip galvanizing is a green process. Zinc is a natural material, and it’s fully recyclable. Unlike paints and other coatings that may release harmful chemicals, hot dip galvanizing is safer for the environment. It provides protection while being a more eco-friendly choice.

Aesthetic Appeal

In addition to being protective, hot dip galvanizing also looks good. The shiny, smooth finish of galvanized metal gives structures a clean, polished look. This can be important for projects that need to look professional and well-maintained, such as fences, gates, or architectural designs.

Why Choose a Hot Dip Galvanizing Company?

Selecting the right hot dip galvanizing company is key to getting the best results. The process requires skill and the right equipment. A reliable company ensures that the metal gets coated properly, with the right thickness and coverage. Working with an experienced hot dip galvanizing company guarantees quality work and saves time. They can also provide helpful advice on caring for your galvanized structures.

Applications of Hot Dip Galvanizing

Hot dip galvanizing is used across many industries. Here are some common uses:

- Construction: Steel beams, bridges, and other infrastructure get galvanized to keep them strong and rust-free.

- Agriculture: Items like gates, fences, and farm equipment get coated to last longer in outdoor conditions.

- Transportation: Vehicles, railings, and other equipment used in transportation benefit from galvanizing to fight rust.

- Energy and Utilities: Power transmission towers and utility poles are often galvanized to ensure they remain sturdy and safe.

How Hot Dip Galvanizing Works

The hot dip galvanizing services process includes several key steps:

- Preparation: First, the metal is cleaned to remove dirt, oil, and rust. This ensures that the zinc bonds properly.

- Pickling: The metal is dipped in a solution that removes any leftover oxide layers.

- Fluxing: Next, the metal is dipped in a flux solution, which prepares the surface for the zinc.

- Galvanizing: The metal is then dipped into molten zinc. The zinc bonds tightly to the metal’s surface.

- Cooling: Finally, the metal cools down, and the zinc coating hardens, creating a strong, protective layer.

The Bottom Line: Why Galvanizing Matters

Hot dip galvanizing is a crucial process for protecting metal structures. It offers outstanding resistance to corrosion, extends the life of metal items, and reduces maintenance costs. This process not only protects your metal structures but also makes them stronger and more durable. It’s an affordable solution for any project where metal is exposed to tough weather or conditions.

By investing in hot dip galvanizing, you are ensuring the longevity of your structures and saving money in the long run. It’s a smart choice for anyone who wants their metal equipment, infrastructure, or products to last longer and stay strong. If you want reliable, cost-effective protection for your metal items, hot dip galvanizing services are essential.

At VG Steel, we provide top-quality galvanizing services to ensure your metal structures stay protected and durable. Get in touch with us today to learn more about how we can help safeguard your metal projects.